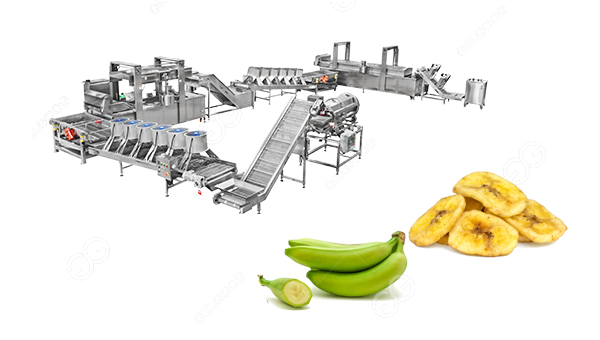

Banana chips, a popular snack enjoyed globally, undergo a meticulous production process in factories to ensure quality, taste, and consistency. The transformation from fresh bananas to crispy chips involves several stages, each demanding precision and attention to detail. But what is the production process of banana chips?

Raw material selection:

The production process begins with the careful selection of raw materials – unripe and firm bananas. Quality control measures are implemented at this stage to ensure that only the best bananas make it to the production line.

Peeling and slicing:

Once the bananas are sorted, they undergo the peeling process. Automated machines efficiently remove the peel, leaving the raw fruit ready for slicing. Advanced slicing machines then cut the bananas into thin, uniform slices. Consistency in slice thickness is crucial for an even frying process.

Pre-treatment:

Banana slices are often subjected to pre-treatment steps to enhance their flavor, color, and shelf life. This may involve dipping the slices in a solution containing citric acid or ascorbic acid to prevent oxidation and browning. Some manufacturers may also use sugar solutions or saltwater brines to add specific flavors to the chips.

Frying:

Frying is a critical step in the production process, responsible for giving banana chips their characteristic crispiness. The banana slices are submerged in hot oil, usually vegetable oil, at precise temperatures. The frying time is carefully monitored to achieve the desired texture and color. Continuous fryers ensure a consistent product by regulating oil temperature and maintaining a steady production flow.

Seasoning and flavoring:

After frying, the banana chips move to the seasoning and flavoring stage. This is where the chips can take on a variety of flavors, from traditional salted options to more exotic choices like barbecue or chili. Seasonings are often applied using a tumbling drum or seasoning drum, ensuring an even coating on each chip.

Cooling and packaging:

The freshly seasoned banana chips are then cooled to room temperature to halt any residual cooking processes. Cooling is typically done using conveyors or cooling tunnels. Once cooled, the chips are ready for packaging. Advanced packaging machinery ensures that the chips are sealed in airtight bags or containers, preserving their freshness and preventing moisture absorption.

Quality control:

Throughout the production process, quality control is paramount. Automated systems and trained personnel constantly monitor parameters such as slice thickness, frying time, seasoning distribution, and packaging integrity. This rigorous quality control ensures that every batch meets the standards set by the manufacturer.

The production process of banana chips in a factory is a harmonious blend of technology, precision, and craftsmanship. From the careful selection of raw materials to the final packaging, each stage plays a crucial role in delivering the crispy, flavorful banana chips that consumers love. If you need the plantain chips processing line for your business, contact us now.