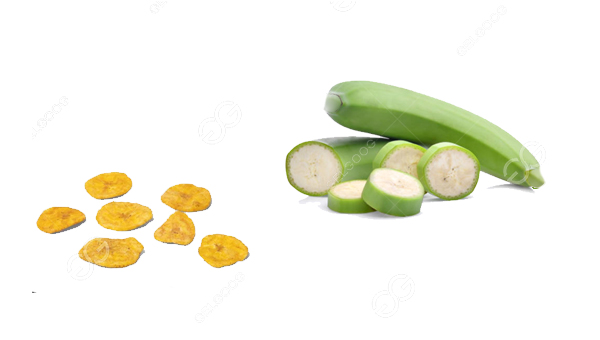

Plantain chips, a popular snack in many parts of the world, have gained widespread acclaim for their delicious taste and crispy texture. Entrepreneurs and food manufacturers looking to venture into the production of plantain chips must carefully evaluate the costs associated with setting up a production line. This article will focus on understanding the plantain chips production line costs involved, including machine costs, transportation costs, and the impact of different models on the overall investment.

Machine costs:

Setting up a plantain chips production line requires the acquisition of specialized machinery to handle various stages of the production process. Key machines include:

A. Peeling machine: This is used to remove the skin from plantains efficiently. Costs for peeling machines can vary based on capacity, ranging from small-scale manual machines to large-scale automated units.

B. Slicing machine: Slicing plantains uniformly is crucial for consistent product quality. The cost of a slicing machine depends on its capacity and level of automation.

C. Frying machine: Plantain chips are typically deep-fried to achieve the desired crispiness. Frying machines come in different sizes and configurations, impacting their costs.

D. Packaging machine: Efficient packaging is essential for preserving the freshness and quality of plantain chips. Packaging machines can range from manual to fully automated systems.

The overall machine cost can vary significantly based on the production capacity and the level of automation desired. High-capacity, automated machines generally entail higher initial investments but may result in cost savings over the long term due to increased efficiency.

Transportation costs:

Transportation costs play a crucial role in the overall investment for a plantain chips production line. Factors influencing transportation costs include:

A. Location of suppliers: The proximity of machine suppliers affects transportation costs. Choosing suppliers closer to the production facility can reduce shipping expenses.

B. Importing machinery: If the chosen machinery is not locally manufactured, import duties, shipping fees, and customs clearance costs must be considered.

C. Delivery to production site: The distance between the supplier and the production site will impact transportation costs. Bulkier and heavier machinery may incur higher shipping expenses.

D. Installation services: If the machinery requires professional installation, the cost of transporting technicians to the production site should be factored in.

Model variations:

Different models of plantain chips production lines are available in the market, catering to varying production capacities and levels of automation. The choice of model can significantly affect overall costs:

A. Small-scale manual models: Suitable for startups or small businesses with limited capital. These models generally have lower upfront costs but may require more labor.

B. Medium-scale semi-automated models: Balancing efficiency and affordability, these models offer a middle ground in terms of cost and automation.

C. Large-scale fully automated models: Geared towards high-volume production, these models involve a higher initial investment but can result in cost savings through increased efficiency and reduced labor requirements.

When embarking on the establishment of a plantain chips production line, careful consideration of machinery costs, transportation costs, and model variations is essential. Entrepreneurs should conduct a thorough analysis based on their production goals, budget constraints, and long-term business objectives to make informed decisions about the most suitable and cost-effective setup for their plantain chips production venture.