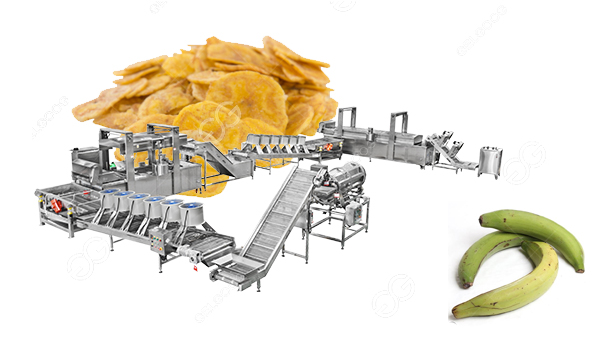

Plantain chips are a popular and delicious snack enjoyed by people all around the world. If you’re interested in producing crispy plantain chips on a large scale, you’ll need a professional plantain chips production line. In this article, we will walk you through how to make crispy plantain chips, using specialized equipment designed for high-volume production.

Ingredients and equipment:

To get started, you’ll need the following ingredients and equipment:

Ingredients:

- Green plantains

- Vegetable oil for frying

- Salt and seasonings (optional)

Equipment:

- Plantain peeling machine

- Slicing machine

- Blanching machine

- De-watering machine

- Frying machine

- Seasoning machine

- Packaging equipment

The process:

- Plantain selection: Choose high-quality green plantains, depending on the type of plantain chips you want to produce.

- Peeling and slicing: The plantains need to be peeled and sliced uniformly. A plantain peeling machine and slicing machine will help maintain consistency in the size and shape of the chips.

- Blanching: Blanching involves immersing the sliced plantains in hot water for a short period to remove excess starch and to partially cook them. This step helps in achieving the desired texture and reduces the oil absorption during frying.

- De-watering: After blanching, the plantains need to be de-watered to remove excess moisture. A de-watering machine is used to achieve the right moisture content for frying.

- Frying: The plantain slices are then transferred to the frying machine, which maintains a consistent temperature for frying. Vegetable oil is used for frying, and the chips should be fried until they turn golden brown and crispy.

- Seasoning: Once the chips are fried, you can add salt and optional seasonings for flavor. A seasoning machine evenly coats the chips with the desired seasonings.

- Packaging: Finally, the seasoned plantain chips are ready for packaging. High-quality packaging equipment is essential to maintain the freshness and quality of the chips.

- Quality control: Throughout the production process, it’s important to implement quality control measures. This includes inspecting the plantains for any defects, monitoring the frying process, and conducting taste tests to ensure the chips meet the desired flavor and texture standards.

- Hygiene and safety: Maintaining high standards of hygiene and safety is crucial in a plantain chips factory. Regular equipment cleaning, sanitation procedures, and employee training in food safety protocols are essential to prevent contamination.

- Scaling up: With the right production line and equipment, you can scale up your plantain chip production to meet market demands. You can also experiment with different flavors and packaging options to diversify your product range.

Producing crispy plantain chips using a professional plantain chips production line is a systematic process that requires specialized equipment and careful attention to quality control, hygiene, and safety. With the right setup and dedication, you can create a successful plantain chip manufacturing operation to supply this tasty snack to consumers worldwide.