With the rise of millennials and Gen Z, new sensory experiences have increasingly become a strong demand for consumers. Capturing the consumers’ curiosity, and balancing and enriching the taste of the product, novel and salty banana chips such as mustard, durian, and chili have appeared one after another, and they seem to have achieved good results. For food processing companies, what are the main points of the production and processing of personalized banana chips? What does the banana chips production cost?

How Much Does The Production Cost Of Banana Chips

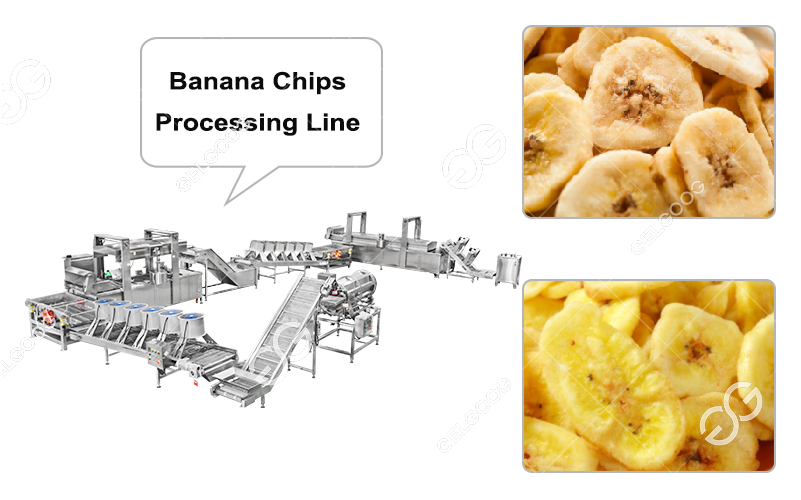

The machines used in the production of banana chips mainly include banana slicers, air dryers, seasoning machines, dryers and other machinery. They have different specifications, and different models can be selected according to the output demand. Different models have different prices. Generally speaking, it is relatively advantageous to choose the finished product price.

However, if you have individual needs, you can directly contact our company for detailed solutions, and we will provide modular design for free matching and combination.

Manufacturing Process Of Banana Chips

1. Raw material and slice processing: The raw material for processing dried bananas requires a high degree of maturity, that is, the period when it reaches edible maturity, good color and flavor. First, pick out the rotten and diseased bananas, then use a banana slicer for peeling and slicing.

2. Color protection treatment: The banana pulp contains polyphenols, even if it is a ripe banana, there are still polyphenols in the pulp, which will cause browning during the processing and storage of finished products. In order to obtain products with good color, it is necessary to carry out color protection treatment, but the main purpose is to prevent the banana chips from turning brown.

3. Air-dried banana slices: Use the wind generated by the air dryer to blow the moisture off the surface of the banana slices. With the conveyor belt with variable frequency to adjust the speed, it is set as a flat net conveying according to the properties of banana slices.

4. Banana chips frying: Deep frying results in crispy and delicious banana slices with a more unique flavor.

5. Banana slices to taste: The seasoning machine is mainly used for the stirring of seasoning powder or the powder coating and blending of raw materials in the later stage of banana slice processing. The whole machine is made of stainless steel, with reasonable structure, firm welding, bright surface, easy cleaning and no noise.

How To Buy a Banana Chips Production Line?

Our company is a banana chip processing solution provider. The above-mentioned banana slicer, air dryer, seasoning machine, dryer and other technologies are mature. Different specifications and combinations can be selected according to the output, and can also be customized according to the actual production situation. Providing customized services for various food industry enterprises is one of our outstanding capabilities and advantages. We provide professional system design and customized equipment according to different customer needs. If you want to get the production cost of banana chips, please leave us a message!

i require a fully automatic banana chips making plant

I REQUIRED a automatic banana chips plant

I required banana chips plant please send plant and price details