Description

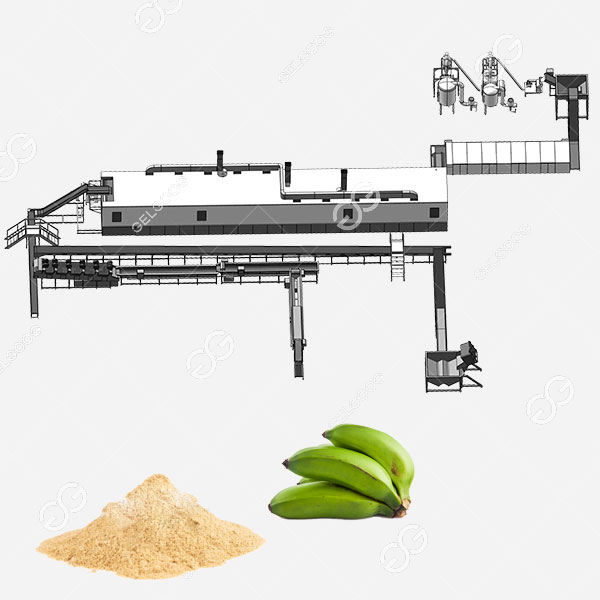

The plantain flour processing plant is a modernised processing facility specifically designed to transform raw plantains into a fine, easily storable powdered product. This processing plant enables the complete processing of raw plantains, encompassing washing, peeling, slicing, blanching, drying, grinding, and packaging.

Workflow of the Plantain Flour Processing Plant:

- Raw Material Inspection and Cleaning

Unripe plantain are first sorted, with any rotten, diseased or overripe specimens removed to ensure consistent product quality. They are then conveyed to washing equipment to remove surface dirt and impurities.

- Peeling

As the selected plantain are less ripe, they are typically peeled by hand after blanching. Blanching facilitates separation of the peel from the flesh.

- Slicing

The peeled plantain are sliced to enable rapid drying in subsequent stages.

- Drying Process

Drying constitutes the core step in plantain flour processing, typically employing hot-air drying. Alternative drying methods may be selected according to specific customer requirements. The moisture content of dried plantain slices is generally controlled below 8%.

- Grinding and Sieving

Dry plantain slices are pulverised into fine powder using a grinder, then sieved through a vibrating screen to achieve the specified particle size—such as 60 mesh, 80 mesh, or 120 mesh—suitable for various end-use requirements.

- Metal Detection and Packaging

The flour passes through a metal detector to ensure food safety. It is subsequently packaged in measured quantities using automated packaging machinery.

Characteristics of the Plantain Processing Plant:

- Fully automated, continuous production: Equipment is seamlessly interconnected via conveyor systems, enabling continuous processing from plantain feed-in to finished product packaging. This significantly boosts output capacity, reduces labour costs, and ensures hygienic production.

- Finely Ground, Uniform Flour with No Lumps: Employing high-efficiency grinding and screening systems, this plantain flour processing plantyields plantain flour with consistent, fine particles and excellent flowability.

- Customisable Output Capacity: We offer multiple production configurations ranging from small-scale processing plant (100–200 kg/h) to large industrial lines (500–2000 kg/h), catering to both start-ups and established factories.

We fully understand that each client’s plantain variety, ripeness, yield, and intended end-product application differ. Therefore, we offer bespoke plantain flour processing plant design services to ensure every stage aligns with your specific requirements.

Simply provide us with the following details, and we shall plan your complete production line free of charge:

- Plantain variety and ripeness?

- Projected raw material volume and target output?

- End-use application (instant powder, infant formula, baking ingredients, etc.)?

- Flour fineness requirements?

- Workshop spatial layout?

Based on your raw material condition and target product, we shall deliver suitable equipment configurations, process flow diagrams, project investment budgets, and installation guidance.

Reviews

There are no reviews yet.